Meeting standard requirements

Updated 04/2024 – This is a brief overview of a number of standards which include information on aspects of slip resistance. The reader should check the details of any standard they are interested in by obtaining and carefully reading an up to date copy of that standard. British standards can be obtained from BSI. European standards can be obtained from CEN and International standards can be obtained from ISO. Several members of the UKSRG currently work on various standard committees and working groups. Please send an enquiry to the Secretary if you would like more information.

The UK Slip Resistance Group recommends using a pendulum to measure slip resistance in line with HSE guidance (http://www.hse.gov.uk/pubns/geis2.htm), however, this may not fulfil all the requirements manufacturers need to bring their products to market. Many products have to meet product standards, UKCA and CE marking and customer requirements and to meet these requirements there are many standards and test methods.

In most cases standards will relate to the product type and if sold in Europe will be a requirement of the Construction Products Regulation meaning a CE mark is required. If sold in the UK a UKCA mark is required (a CE mark may also be acceptable). Many tests however are engrained in building regulations, architect’s requirements, legislation or ‘just because that’s the way it has always been done’.

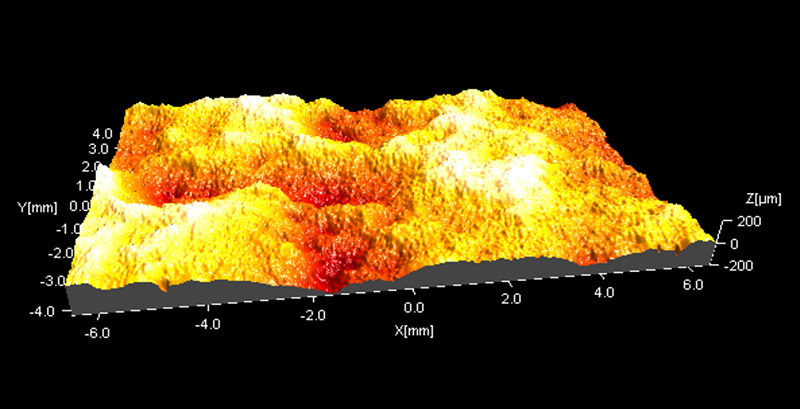

3D micro profile images of a surface – Tests to see if standards are fullfilled can go into the macromolecular details if required.

BS EN 16165: 2021 – Determination of slip resistance of pedestrian surfaces — Methods of evaluation

This standard contains three test methods, the ramp test, pendulum test and tribometer test. The shod ramp test uses standard footwear with a contaminant of oil. In the barefoot ramp test the operators walk with bare feet on a contaminant of 1g/litre soap solution sprayed onto the surface at a rate of 6 litres per minute. The pendulum test methology is relatively close to the UK Slip Resistance Guidelines but uses slider 96 and slider 57 (the latter being a compromise between RAPRA’s slider 55 and BAM’s slider 59). It also gives the choice to do either dry or wet measurements or both. The UKSRG would recommend both are done. This standard is now a European standard and has replaced BS 7976, BS EN 13893 (tribometer test), DIN 51130 and DIN 51097 and is at present already referenced by a number of European requirement standards including ceramic tiles (EN 14411) and resilient floors (EN 13845)

BS 7976: 2002+A1: 2013 – Pendulum testers — Part 2: Method of operation

This test method describes how to use the pendulum and was the most commonly used standard in the UK. It is used to test the slip resistance of pedestrian surfaces. It has now been replaced by BS EN 16165: 2021

BS EN 14411: 2016 – Ceramic tiles — Definition, classification, characteristics, assessment and verification of constancy of performance and marking

This is the ceramic tile requirements standard. Slip resistance is a declared value based on the methods described in EN 16165.

BS EN 13845: 2017 – Resilient floor coverings – Polyvinyl chloride floor coverings with particle based enhanced slip resistance – Specification

This standard requires two slip tests

- Ramp based test (Appendix C) using either footwear with a slider 96 rubber sole or barefoot and a contaminant of 0.1% soap solution sprayed onto the surface at a rate of 6 litres per minute.

- The pendulum test as described in EN 16165 using either slider 96 (shod areas) or slider 57 (barefoot areas).

In the ramp test two operators walk in a controlled manner at a set pace over a one metre distance of the surface under test. The operators take four half gait steps forward and backward twice. If there is no slip the angle of the surface is raised by approximately one degree and the process is repeated until a slip occurs. Surfaces have to meet the requirements, for shod areas, ≥20° and ≥36 pendulum to be classed as ESf and, for barefoot areas, ≥15° and ≥36 pendulum to be classed as ESb.

BS EN 13893: 2002 – Resilient, laminate and textile floor coverings. Measurement of dynamic coefficient of friction on dry floor surfaces

This test uses a tribometer with leather and rubber sliders and tests in the dry only. For CE marking a minimum requirement of 0.3 is required. The standard will be eventually superseded by BS EN 16165.

BS EN 12057:2015 – Natural stone products — Modular tiles — Requirements

This is the requirements standard for natural stone used for modular tiles. It refers to EN 16165 as the test method for measuring slip resistance. It should be noted that BS EN 16165 relates to pedestrian slipping but testing with slider 57 will provide the information for the skid resistance requirement of BS EN 12057.

However, the following standard also exists,

BS EN 14231: 2003 – Natural stone test methods — Determination of the slip resistance by means of the pendulum tester

This test is carried out using a pendulum with a slider 55 rubber in the dry and the wet. Six specimens are tested in two directions at 180° to each other. The wet test is carried out after soaking the samples in water. It is intended for natural stone used in buildings for flooring.

BS EN 1341: 2012 – Slabs of natural stone for external paving. Requirements and test methods

This test is carried out using a pendulum with a slider 55 rubber in the wet only, using the method in BS EN 14231. The requirements say that the surface should be greater than 35 in the wet but it is wise to check with the specifier as the requirements can differ depending on the application.

BS EN 13036-4: 2011 – Road and airfield surface characteristics — Test methods Part 4: Method for measurement of slip/skid resistance of a surface: The pendulum test

A pendulum test which uses slider 96 or slider 57 testing in the wet only and in only one direction. It is used for slip (pedestrians) and skid (vehicles) resistance.

DD CEN/TS 15676: 2007 – Wood flooring. Slip resistance. Pendulum test

A pendulum test using slider 55. The slider is conditioned on a surface which has a pendulum value of greater than forty on the C scale. The test is usually carried out in the dry but there is an annex for wet testing.

BS 8445: 2012 – Bath and shower mats. Testing. Assessment of slip resistance properties

This test is a ramp test carried out barefoot with a contaminant of 0.01% soap solution. The bath mat is placed on an acrylic bath surface on the ramp. Two test two operators walk in a controlled manner at a set pace over a one metre distance of the surface under test. The operators take four half gait steps forward and backward twice. If there is no slip the angle of the surface is raised by approximately one degree and the process is repeated until a slip occurs or until the bath mat no longer adheres to the acrylic surface. The angle at which a slip or product failure occurs determines the class as comfort (14 to 19 degrees) or slip resistant (20+ degrees).

BS EN 1344: 2013 – Clay pavers — Requirements and test methods

This test uses a pendulum with slider 57 and follows the test method as described in prEN 16165. The surfaces are given a class U0, U1, U2 or U3 depending on the result.

- U0 = no requirement

- U1 = ≥35

- U2 = ≥45

- U3 = ≥55

BS EN 1338: 2003 – Concrete paving blocks — Requirements and test methods

This standard states that concrete products will provide satisfactory slip resistance throughout the life of the product unless a major proportion of the aggregate, which will polish easily, has been exposed on the surface. However, if slip resistance is required then it contains an annex which describes using a pendulum with a slider 55 in the wet after the sample has been soaked for a set period. The test is carried out in two directions at 180° to each other.

BS EN 1339: 2003 – Concrete paving flags — Requirements and test methods

The standard for concrete slabs follows the same format as BS EN 1338 for concrete paving blocks with the additional information:

| PTV | Potential for slip |

| <19 | High |

| 20 to 39 | Moderate |

| 40 to 74 | Low |

| >75 | Extremely low |

DIN 51097 – Testing of Floor Coverings – Determination of Anti Slip Properties – Wet Loaded Barefoot Areas – Walking Method – Ramp Test

A ramp test where operators walk with bare feet on a contaminant of 1g/litre soap solution sprayed onto the surface at a rate of 6 litres per minute. Two operators walk in a controlled manner at a set pace over a one metre distance of the surface under test. The operators take four half gait steps forward and backward twice. If there is no slip the angle of the surface is raised by approximately one degree and the process is repeated until a slip occurs. The angle of slip categorises the surface as A (≥12°), B (≥18°) or C (≥24°). It is important to recognise, there is no correlation between this test and the pendulum. This standard has now been superseded by EN 16165 which does not categorise the angle of slip.

DIN 51130 – Testing of Floor Coverings – Determination of Anti Slip Properties – Workrooms and Fields of Activities with Slip Danger – Walking Method – Ramp Test

A ramp test using standard boots with oil as the contaminant. Two operators walk in a controlled manner at a set pace over a one metre distance of the surface under test. The operators take four half gait steps forward and backward twice. If there is no slip the angle of the surface is raised by approximately one degree and the process is repeated until a slip occurs. The angle of slip is then categorised as an R value. The R values range from R9 (the lowest) to R13 (the highest).

- R9 = 6° up to 10°

- R10 = Over 10° up to 19°

- R11 = Over 19° up to 27°

- R12 = Over 27° up to 35°

- R13 = Over 35°

It is important to recognise, there is no correlation between this test and the pendulum. This standard has now been superseded by EN 16165 which does not categorise the angle of slip.

BS 4592-0: 2006+A1: 2012 – Flooring, stair treads and handrails for industrial use. Common design requirements and recommendations for installation

This standard gives the option of either a pendulum or ramp test. The pendulum test is carried out as in BS 7976 (or one would assume BS EN 16165 now BS 7976 has been withdrawn) or the UK Slip Resistance Guidelines. The ramp test is carried out using water as the contaminant (there is a choice to use contaminants that may be used in the area of application) and any, well fitting, commercially available industrial type safety footwear. Two operators walk in a controlled manner at a set pace over a one meter distance of the surface under test. The operators take four half gait steps forward and backward twice. If there is no slip the angle of the surface is raised by approximately one degree and the process is repeated until a slip occurs. From the angle of slip the surfaces are categorised as follows:

- Unsuitable for wet conditions <0.4 Coefficient of friction

- Slip resistant surfaces 4 to <0.6 Coefficient of friction

- Enhanced slip resistant surfaces >0.6 Coefficient of friction

It should be noted that the type of footwear used will heavily influence the result along with any change in contaminant and so results from this test need to be scrutinised carefully.

BS EN 16837: 2018 – Surfaces for sports areas. Determination of linear shoe/surface friction

This is a pendulum test in the dry only using a slider with a hardness (IRHD) of 55±3. EN 14904-2 Surfaces for sports areas. Indoor surfaces for multi-sports use. Specification, once published is expected to be a CE requirement with the following criteria, the sports floor covering shall have a value of linear friction of more than 80 and less than 115.

Many of the above standards will be harmonised in to one standard now EN 16165 has become a European standard. Until that happens it is important, particularly when using a pendulum, to recognise that the pendulum needs to be set up correctly, verified before use and the rubber slider conditioned to ensure consistent results across all standards and operators. Following the UK Slip Resistance Guidelines before testing can ensure that this happens and will not affect the test procedures laid out in the above standards. It is also worthy to note that, although some standards state the use of slider 55 or 57 for the measurement on pedestrian surfaces, in the UK, if an accident were to occur on one of these surfaces in service then the HSE would measure using a pendulum with slider 96 in a shod area and slider 55 in a barefoot area so it may be prudent to test using both sliders (one to satisfy the product requirements and one to satisfy the safety for the intended application). The same applies to measurements taken using a ramp. In addition, there is no correlation between the pendulum method and the ramp method and any verification on a surface once it has been laid and in service, will be carried out using a pendulum.

This article was written by Simon Hall, who is Technical Manager, Physical Testing at LUCIDEON and a Member of the UKSRG. Lucideon Ltd offers a wide range of UKAS accredited testing laboratories to ensure standard requirements are met for quality control, new product developments and on site measurement for existing products in service. (Published 12/2019; reviewed and updated 04/2024)

.

Become a member and get involved in the UK Slip Resistance Group

More