This years Qualicer was at the 5th & 6th March in Castelló, Spain: https://www.qualicer.org/en/ It was the 18th World Congress on Ceramic Tile Quality and…

MoreLatest guidance

UK Slip Resistance Group Guidelines – Issue 6

The UK Slip Resistance Group compiles, publishes and distributes authoritative guidance on how to reliably test the slip resistance of flooring materials. The Assessment of…

More

IEA 2024 – Jeju, Korea (STF) – Abstract Submission Deadline Extended

We would like to inform you that the abstract submission deadline for the IEA 2024 Conference has been extended to March 21st. This extension provides…

More

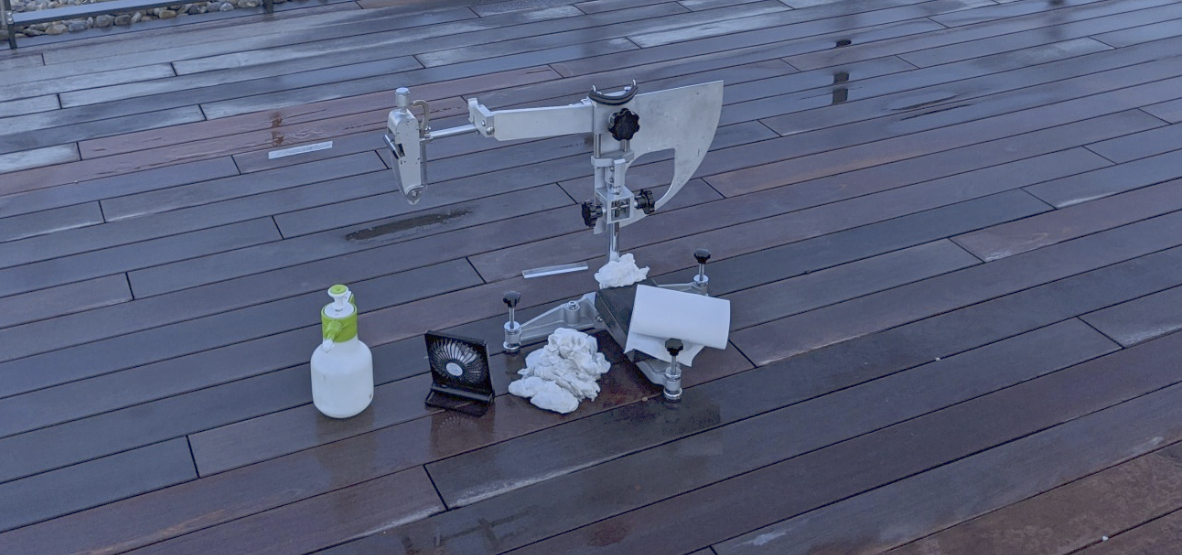

The importance of effective cleaning & maintenance of floors

Slip and trip accidents can be serious and extremely costly – both for building owners and managers and for the victims themselves. Solutions are often simple and implementing an effective cleaning and maintenance programme is usually a cost-effective way of significantly reducing the risk of slips on floors.

More

Liability in a Slipping Case

Ben Powers of Munro Instruments Ltd recently provided expert witness services in a slipping case (H11YJ740). The judgement of that case revealed insights both into…

More

Changes to the EN ISO 20345 standard

Hannah Coe explores the amendments to this standard which may affect safety footwear design and production. Having last been updated in 2011 and, after much…

More

Meeting standard requirements

Updated 04/2024 – This is a brief overview of a number of standards which include information on aspects of slip resistance. The reader should check…

More

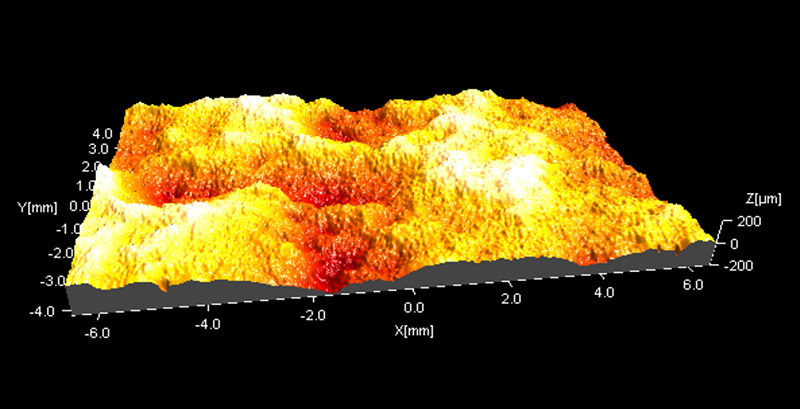

Sustainable slip resistance in resilient vinyl floors

Vinyl Floor Coverings Slip Resistance Many different resilient floor coverings are available with a wide range of performance characteristics and slip claims. It is essential to…

More

Slip resistance of children’s shoes

Mike George explains the differences in slip resistance testing between children’s and adult’s footwear, and the reasons for them. . Falling over is a natural…

More

Making stairs safer

300,000 hospital admissions each year are from stair accidents – This UKSRG document is for any person or organisation involved with the design, specification, construction, installation or maintenance of internal stairs. It gives professional guidance on features of stair safety and has supporting references for further reading.

More